Detailed Explanation of Titanium Anodes

What is a Titanium Anode?

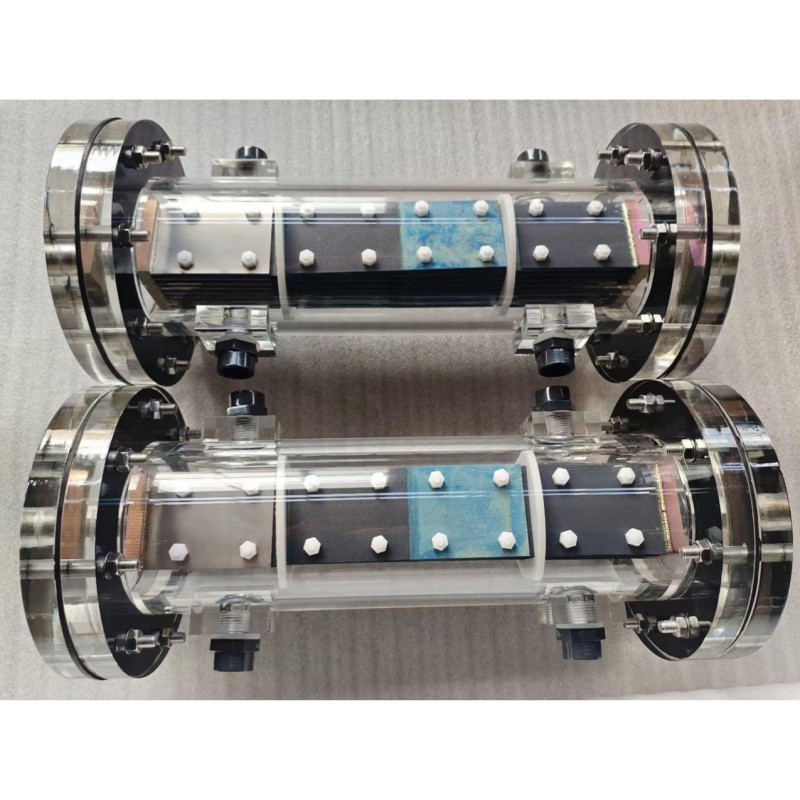

A titanium anode, fully named Titanium-based Metal Oxide Coated Titanium Anode (MMO), is also called a DSA (Dimensionally Stable Anode). It uses titanium as a substrate, coated with a precious metal layer applied by brushing, giving it excellent electrocatalytic activity and conductivity.

Classification of Titanium Anodes:

Classified by the gas evolved at the anode during the electrochemical reaction: those evolving chlorine gas are called chlorine-evolving anodes, such as ruthenium-based coated titanium electrodes. Those evolving oxygen are called oxygen-evolving anodes, such as iridium-based coated titanium electrodes and platinum-coated titanium mesh/plate.

Chlorine-evolving Anodes (Ruthenium-based Coated Titanium Electrodes): Used in electrolytes with high chloride ion content, typically in hydrochloric acid environments, seawater electrolysis, and brine electrolysis environments. Corresponding to our company's products are Ru-Ir-Ti anodes, Ru-Ir-Sn-Ti anodes.

Oxygen-evolving Anodes (Iridium-based Coated Titanium Electrodes): The electrolyte is generally a sulfuric acid environment. Corresponding to our company's products are Ir-Ta anodes, Ta-Sn anodes, and high-iridium anodes.

Platinum-coated Anodes (Platinum Titanium Mesh/Platinum Titanium Plate): Titanium is the base material, coated with the precious metal platinum on the surface. The coating thickness is generally 1-5 micrometers (µm). The mesh specifications for platinum titanium mesh are typically 12.7*4.5mm or 6*3.5mm.

Selection of Anodes: If customers are unsure which anode to use, we need them to provide the working environment and electrolyze:

1. Current density per square meter (current intensity borne by a single anode divided by the electrode surface area).

2. Temperature.

3. pH value.

4. Composition and proportions of the solution.

5. Product being produced or intended use, etc.

What is the function of the metal oxide coating on titanium anodes?

By applying different coatings, it enhances conductivity and electrocatalytic activity, promotes the electrolysis reaction process, and extends the anode's service life in different operating environments, achieving the desired usage effect.

The issue of metal oxide coating thickness on titanium anodes:

The primary component responsible for the electrocatalytic reaction is the precious metal in the coating. Only when the precious metal content meets usage requirements can the normal operation of the anode product be ensured. Thickness is merely an external manifestation, mainly determined by the number of brush-coating passes and the concentration of the solvent. It is not directly linked to the amount of precious metal content. An excessively thick coating can actually become more prone to peeling.

What is anode passivation?

What is the passivation phenomenon of metals? When an iron wire is immersed in dilute nitric acid, it dissolves quickly. However, when placed in concentrated nitric acid, the dissolution almost completely stops. If the iron wire is then returned to the dilute nitric acid, it no longer dissolves. No changes are visible on the wire's surface, even under a microscope. The iron wire is considered to be in a passivated state. During electrochemical operation, an anode has a finite service life. When the voltage rises very high and essentially no current passes through, the anode loses its function. This phenomenon is called anode passivation.

What are the main factors affecting anode service life?

1. Current Density: Current density is inversely proportional to anode life. Higher current leads to shorter anode life. Our company's anodes are designed for a current density within 2000 A/m². It is recommended not to exceed 2000 A/m². Also, avoid frequent current fluctuations.

2. Titanium Substrate: The substrate material is generally pure titanium, requiring TA1 grade or higher. If the substrate purity is insufficient, its corrosion resistance is significantly compromised, greatly affecting the anode's service life.

3. Electrolyte: The electrolyte must not contain fluoride ions (F⁻), cyanide ions (CN⁻), or sulfide ions (S²⁻). Their presence significantly impacts anode life.

4. Polarity Reversal (Current Reversal): Polarity reversal is a common method to clean scale from anodes. By switching polarity, scale attached to the cathode falls off, achieving descaling. When reversing polarity, use a power supply that can slowly switch the positive and negative poles. Instantaneous polarity reversal is prohibited.

5. Frequent Power Interruptions: When no current passes through, prolonged immersion of the coating in the solution can cause significant damage. Therefore, when the anode is idle, it's best to maintain a very small current to keep the circuit active. For long-term non-use, remove the anode from the liquid, rinse it clean with water, dry it, and store it.

6. Mechanical Damage: The anode surface must not have hard damage. Even a small scratch damaging part of the coating can cause the anode to corrode/passivate rapidly, leading to failure. Handle the anode carefully during installation and use to avoid impact.

7. Short Circuit: Contact between the anode and cathode while powered is prohibited. The instantaneous current from a short circuit can be very high, burning out the electrode plates.

8. Temperature: Temperature is also inversely proportional to anode life. Our company's anodes are designed for temperatures of 40-60°C. It is recommended not to exceed 60°C.

Advantages of Titanium Anodes:

1. Dimensionally stable (substrate does not dissolve), electrode gap remains unchanged, ensuring stable cell voltage.

2. Low operating voltage, reduced electrical energy consumption, saving about 20% compared to lead anodes.

3. High purity of cathode product.

4. Does not generate anode slime, does not contaminate the cell.

Lightweight, reduces labor intensity.

Substrate can be reused.